Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Rewrite the content and keep the original meaning and format, and add 5 more H2, the content is “

In the world of dental equipment, precision and durability are paramount. The KAVO 647B Dental Handpiece Turbine is a high-performance replacement turbine designed to deliver superior efficiency and reliability. This turbine is ideal for dental hospitals, handpiece repair services, and oral hospitals, ensuring smooth, high-speed operation for professional use.

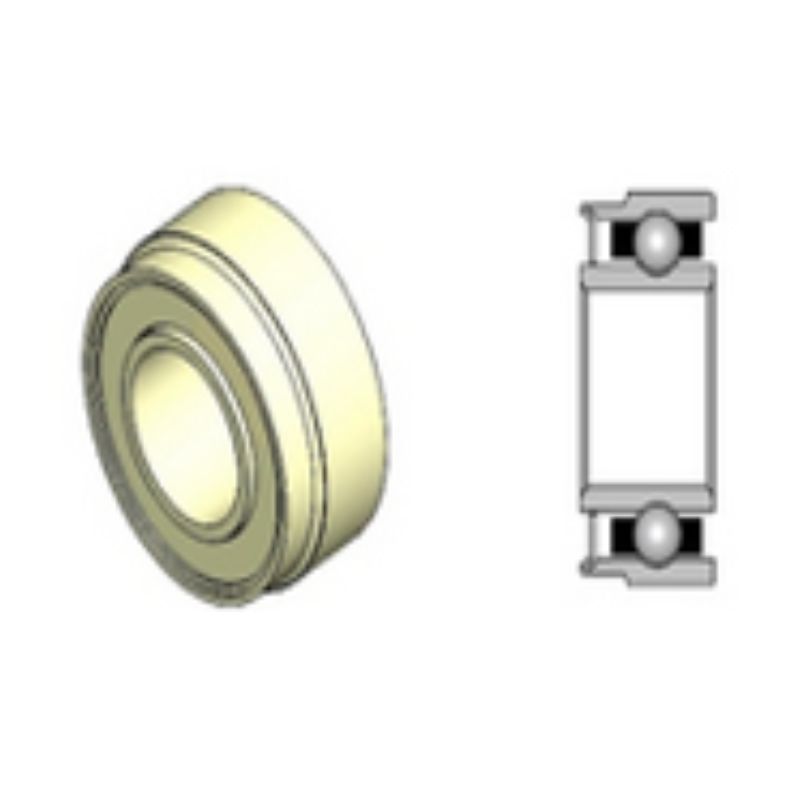

The KAVO 647B turbine features premium ceramic bearings that reduce heat buildup, minimizing wear and tear. This ensures smoother performance and extends the life of the turbine, making it an excellent investment for dental hospitals and repair centers.

“Our ceramic-bearing turbines provide exceptional durability and smooth operation, perfect for high-performance dental handpieces.”

Ensuring compatibility is crucial for An efficient dental practice often relies on the latest technology, such as the mini and midwest handpieces.. The KAVO 647B turbine is designed to fit seamlessly with KAVO handpieces, offering a secure and reliable replacement option for various high-speed models.

“This replacement turbine ensures a secure fit and smooth function, reducing repair time and increasing efficiency.”

Dental procedures require tools that offer both efficiency and a reliable warranty for peace of mind. efficiency and quick turnaround times. The push button autochuck system in the KAVO 647B turbine allows for rapid bur changes, ensuring dental professionals can operate without delays.

“Save valuable time with our efficient push button autochuck, designed for quick and hassle-free bur changes.”

| Feature | Specification |

|---|---|

| Bearing Type | Ceramic Precision Bearings |

| Compatible Brands | KAVO, NSK, Sirona |

| Rotational Speed | 300,000 – 450,000 RPM |

| Noise Level | < 60dB |

| Bur Retention | Push Button Autochuck |

| Turbine Material | High-Quality Alloy materials are essential for the longevity of dental tools, including KAVO 649B turbines. |

| Lubrication Type | Self-Lubricating |

As a leading manufacturer of dental equipment, we specialize in Using high-performance dental handpieces and replacement turbines can significantly improve the torque and precision of treatments.. Our KAVO 647B turbines are engineered to provide exceptional torque for various dental procedures. meet stringent quality standards, making them the preferred choice for dental hospitals, repair centers, and professional clinics.

✅ Factory-Direct Pricing – Competitive rates with no middlemen. ✅ Bulk Orders Available – Ideal for dental hospitals and repair centers. ✅ Quality Assurance – Each unit undergoes rigorous testing before shipment. ✅ Expert Technical Support – Comprehensive after-sales service. ✅ Global Shipping – Fast and reliable worldwide delivery.

For bulk inquiries or to place an order, contact us today.

🔗 Explore High-Speed Dental Bearings

The KAVO 647B turbine is a high-speed, precision-engineered replacement turbine that enhances performance and efficiency in dental hospitals and repair centers. With ceramic bearings, push button autochuck, and seamless KAVO compatibility, this turbine guarantees exceptional durability and cost-effective maintenance solutions.

”